- Home

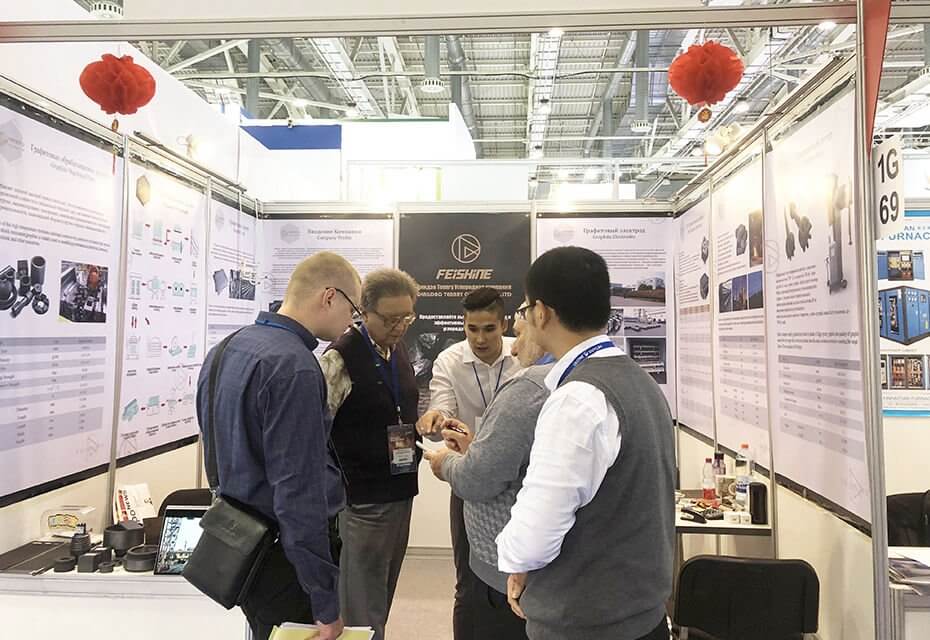

- About

-

Products

- Graphite parts of vacuum furnace

- Graphite bearing

- Graphite mould

- Graphite Sheet

- Graphite rotor

- Graphite material

- Graphite crucible

- Graphite stick

- Graphite column

- Graphite boat

- Graphite sagger

- Thermal field of graphite

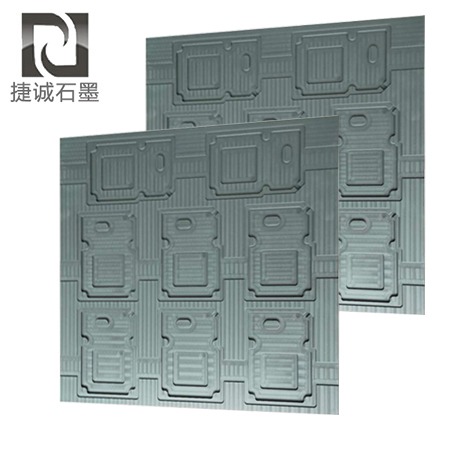

- Graphite plate

- Graphite Powder

- PECVD graphite boat

- Graphite products

- Carbon carbon composites

- Blogs

- Contact

一级标题

一级标题